To strengthen the theoretical knowledge and provide aid in research and consultancy projects, the department maintains well-equipped laboratories .The laboratories are:

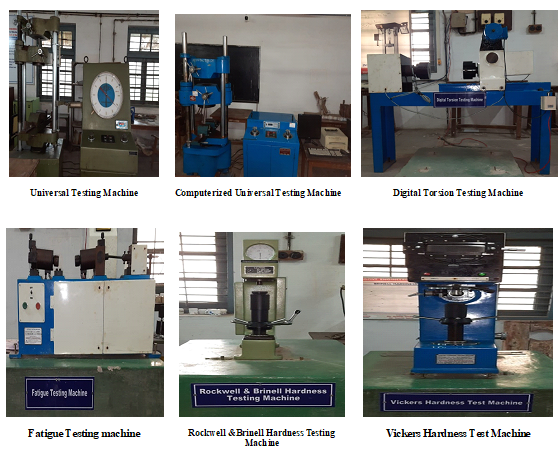

Material Testing Lab

Material Testing Lab

Material Testing Lab is located inthe Mechanical Engineering Department of Rewa Engineering College,

where mechanical properties of various ductile and brittle materialsaretested.

This laboratory is dedicated to the part of BT-203 (Basic Mechanical Engineering) course,

which is taught in the first year (all branches) and ME-304 (Strength of Materials),

which is taught in IIIrd semester as well as research/project work.

Consultancy work of various government and private firms is done in this lab.

List of Experiments

- 1. Standard tensile test on MS and CI test specimen with the help of UTM.

- 2. Direct/ cross shear test on MS and CI specimen.

- 3. Transverse bending test on wooden beams to obtain modulus of rupture.

- 4. Fatigue test.

- 5. Rockwell hardness test.

- 6. Brinell hardness test

- 7. Vickers hardness test.

- 8. Izod/Charpy test.

Dynamics of Machines Lab

Dynamics of Machines Lab

Mechanisms form the basis of any machine and it is an assemblage of rigid bodies

so that they move upon each other with definite relative motion. Objectives of Dynamics of Machines Lab are to impart practical

knowledge on design and analysis of mechanisms for the specified type of motion in a machine,with the study of rigid bodies,

motions and forces for the transmission systems. Various experiments with governors,

gyroscopes and balancing machines are available to understand machine dynamics.

List of Experiments

- 1. Determination of characteristic curve of a sleeve position against speed of rotation of all governors.

- 2. To study the effect of varying mass of the center sleeve in porter and proell governor.

- 3. To study the effect of varying the initial spring compression in hartnell governor.

- 4. Determination of characteristics curves of radius of rotation against controlling force for all governors.

- 5. Observation of gyroscopic behavior.

- 6. Study of cam analyzer.

- 7. Study of conical friction clutch model.

- 8. To measure epicyclic gear ratio between input and output shafts.

-

9. Study of models of Davis and Ackerman steering mechanism.

Vibration Lab

Vibration Lab

This laboratory introduces the basic principles involved in free vibration. The universal vibration apparatus consists of a spring-mass damper system.

The laboratory is designed to provide the students with insight into the influence of the parameters involved in the governing equations of the system. Various experiments will be run during the laboratory period.

The students will be expected to calculate data based on the theory and compare that data with experimental results.

List of Experiments

- 1. To find out effect of load on natural frequency of vibrations of a lever pin supported at one end carrying adjustable load on a vertical screwed bar and spring supported at some intermediate point (i) when the dead weight of rods is neglected and (ii) when their dead weight is taken into account.

- 2. To find out frequency of damped free vibrations and rate of decay of vibration-amplitude in the system.

- 3. To find out natural frequency and damped free frequency of a torsion pendulum, and hence to find out coefficient of damping of the oil.

- 4. To observe the phenomenon of ‘whirl’ in a horizontal light shaft and to determine the critical speed of the shaft.

- 5. To observe the mode shapes of a spring-connected, double pendulum, and hence to demonstrate the phenomenon of beats.

- 6. To demonstrate the principle of tuned Undamped Dynamic Vibration Absorber and to determine the effect of mass-ratio (of main and auxiliary mass) on the spread of the resulting natural frequencies.

Materials and Measurement Lab

Materials and Measurement Lab

Materials and Measurement Lab is located in the Mechanical Engineering Department of Rewa Engineering College,

where analysis of different materials and measurement of mechanical properties is done.

The laboratory is also for students who need help during building their major/minor projects.

This laboratory is dedicated to courses that are given in the III and IV semesters.

List of Experiments

- 1. Flow measurement of fluid using Venturi meter and orifice meter.

- 2. Torque measurement using drill tool dynamometer

- 3. Angle measurement using sine bar and slip gauges.

- 4. Temperature measurement using thermocouple.

- 5. Metallographic studies – Study of Optical microscope, optically flat surface preparation, etching reagents, grain size, microstructures, Image analysis.

- 6. Measuring the Carbon and sulphur by Strauhlin’s apparatus

- 7. Different heat treatment cycles using an electric furnace

- 8. Study of spectrophotometer instrument

Production Engineering Lab

Production Engineering Lab

Production engineering Laboratory (PEL) is a support facility for research and educational activities.

The lab provides experimental and practical works to the students of the Rewa Engineering College,

Rewa (M.P). The vision of this lab is to achieve knowledge of metal cutting

theory of basic fabrication of materials and education by combining local resources and expertise

to provide solutions to complex technical challenges in product design, enhancement, utilization,

and identification. First, 3rd and 6thsemester students work in this lab for practical work as per the

RGPV syllabus.

We have following instruments in this lab

- 1. Lathe machine

- 2. Radial drill machine

- 3. Grinding machines

- 4. Welding machine

- 5. Power hacksaw machine

List of Experiments

- 1. Study of basic machining

- 2. Taper turning operation by using lathe machine

- 3. External thread cutting by using lathe machine

- 4. Study of different kind of joining process by using welding machine

- 5. Study of drilling machine

Heat Transfer Lab

Heat Transfer Lab

This lab helps the students to understand the basic concepts about heat and mass transfer: conduction,

convection, radiation, diffusion and leaching. To enhance the practical knowledge about industrial equipment,

students perform the practicals on Heat Exchangers, etc.

Experiments performed in this lab help students to learn theoretical concepts of the given subject easily.

List of Experiments

- 1. Parallel and counter flow heat exchanger apparatus

- 2. Critical heat flux rig

- 3. Filmwise and dropwise condensation

- 4. Unsteady heat conduction

- 5. Heat transfer through composite wall

- 6. Emissivity of the surface apparatus

- 7. Heat transfer in forced convection through pipe

- 8. Heat transfer from pin fin

- 9. Heat Transfer in natural convection

- 10. Stefan-Boltzman Apparatus

- 11. Thermal conductivity of Metal Rod

- 12. Pool boiling test rig

Refrigeration and Air Conditioning Lab

Refrigeration and Air Conditioning Lab

This lab helps the students to understand the basic concepts about Refrigeration & Air Conditioning: Vapour compression system, Psychometry and Air conditioning.

List of Experiments

- 1. General Study of vapor compression refrigeration system

- 2. General Study of Ice Plant

- 3. General Study and working of cold storage

- 4. General Study of Trane Air Conditioner (Package Type).

- 5. General Study of Electrolux Refrigeration

- 6. General Study One tone Thermax refrigeration unit.

- 7. General Study of Water cooler

- 8. General Study of Psychrometers (Absorption type)

- 9. General Study of Leak Detectors (Halide Torch).

- 10. General Study and working of Gas charging Rig.

- 11. General Study of window Air Conditioner.

- 12. General Study and working of Vapor compression Air conditioning Test rig.

IC Engine Lab

IC Engine Lab:

Internal Combustion Engine Laboratory is a well-equipped laboratory which provides ideas on practice of handling IC engines

and measuring the performance parameters.The laboratory is equipped with number of equipment & experimental setups to

study the fundamental & applied aspects of the internal combustion (IC) engines.This lab has computerized petrol/diesel

engine test rigs to calculate various efficiency parameters of two stroke/ four stroke petrol and diesel engine.

This lab also has various models of carburetors, fuel pumps, etc. for the study of engines.

Apart from curriculum, some additional experimental setups are there which help the students to enhance their knowledge.

Students also get opportunity to implement their ideas through various application oriented micro projects.

List of Experiments

- 1. Determination of Valve timing diagram

- 2. Load test on Petrol Engine

- 3. Heat Balance of SI engine

- 4. Heat Balance of CI Engine

- 5. Study of Battery Ignition system and Electronic Ignition System

- 6. Study of Diesel fuel pump

- 7. Study of Diesel fuel injectors

- 8. Study of Carburetors

- 9. Study of Fuel Injection system in SI Engine

- 10. Study of lubricating system in CI Engine

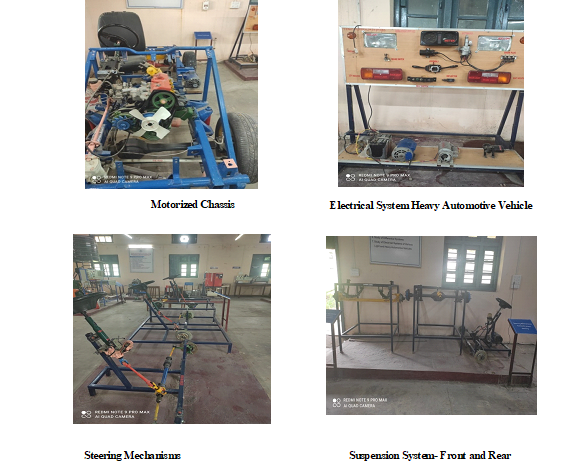

Automobile Engineering Lab

Automobile Engineering Laboratory

The lab is well-equipped and enables students to understand the fundamentals of Automotive Engineering which includes basic structure,

body style, power transmission and wheel & tyre assembly.This lab facilitates the study of the transmission system, suspension system,

steering system, electrical system of an automobile.

List of Major Equipment

- 1. Motorized Chassis

- 2. Suspension System- Front and Rear Suspension System

- 3. Steering Mechanism

i. Rack and Pinion Type

ii. Recirculating ball type

iii. Hydraulic power

iv. Electronic Power

- 4. Transmission Systems

i. Constant Mesh

ii. Synchro Mesh

- 5. Automatic Gear Box

- 6. Differential System

i. Light Commercial Vehicles

ii. Heavy Commercial Vehicles

- 7. Electrical System

i. Light Automotive Vehicle

ii. Heavy Automotive Vehicle

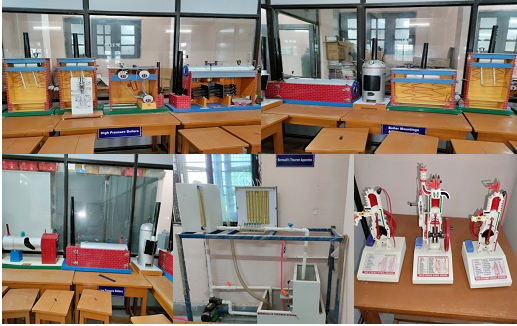

Basic Mechanical/Heat Engines Lab

Basic Mechanical/Heat Engines Lab

Mechanical Engineering is often considered as the most basic type of engineering work.

It is probably the first branch of engineering which has vast applications in all fields.

Mechanical engineers were responsible for Industrial Revolution and innovations like the steam engine, internal combustion engines,

turbines, compressors, pneumatic machines, machine tools, refrigeration and air conditioning systemsetc,are done by mechanical engineers.

The objective of this lab is to provide good knowledge on Basic Mechanical Engineering.

The lab is well equipped and enables students to understand the working of different mechanical equipments.

The lab contain Bernoulli’s apparatus, models of different types of boilers, their mountings and accessories.

List of Experiments:

- 1. Study of Universal Testing machines.

- 2. Linear and Angular measurement using, Micrometer, Slip Gauges, Dial Gauge and Sine-bar.

- 3. Study of Lathe Machine.

- 4. Study of Drilling Machines.

- 5. Verification of Bernoulli’s Theorem.

- 6. Study of various types of Boilers.

- 7. Study of different IC Engines.

- 8. Study of different types of Boilers Mountings and accessories

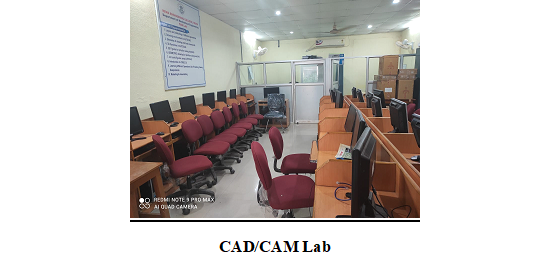

CAD/CAM Lab

CAD/CAM Laboratory

To familiarize the use of computer software and application package,

the mechanical engineering department has CAD/CAM lab which has software like Solid Edge, FEMAP with NX Nastran and NX CAM Express.

A well-equipped computer lab with advanced facilities is established for the benefit of the mechanical engineering students.

Major Equipment:

- 1. Server

- 2. Workstations

- 3. PCs

List of Experiments:

- 1. Create a2D viewof thegiven diagram

- 2. Draw thebasicsketch ofthe solid model

- 3. Draw thebasicsketchforthe revolved solid model

- 4. Draw thesketchfor the 3Dmodelingofsolid model of given dimension

Applied Mechanics Lab

Applied Mechanics Laboratory

Applied Mechanics Lab is located in Mechanical Engineering Department of Rewa Engineering College, where laws of mechanics are experimentally verified .This Lab is dedicated to part of BT-204 (Basic Civil Engineering and Mechanics) course which is taught in first year (all branches).

Major Equipment:

- 1. Universal Force Table

- 2. Flywheel apparatus

- 3. Lever apparatus

- 4. Jib Crane Apparatus

- 5. Combined Inclined Plane & Friction Apparatus

- 6. Bell crank Lever Apparatus

- 7. Bending Moment Apparatus

List of Experiments:

- 1. Verify the condition of equilibrium of a body under the action of coplanar concurrent forces using universal force table.

- 2. Calculate moment of inertia of flywheel about its axis of rotation

- 3. Verify principle of moments of lever apparatus.

- 4. Verify Lami’s theorem using Jib Crane apparatus

- 5. Calculate coefficient of static friction of different material pairs using Combined Inclined Plane & Friction Apparatus.

- 6. Verify principle of moments of Bell Crank lever apparatus.

- 7. Compare the theoretical internal moment with the measured bending moment for a beam under various loads.

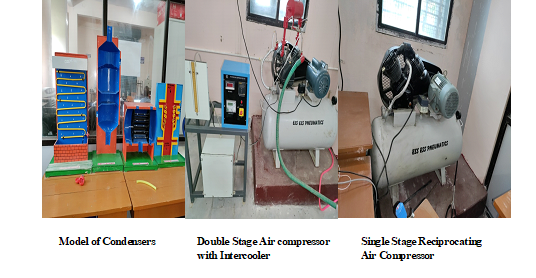

Thermal Engineering and Gas Dynamics Lab

Thermal Engineering and Gas Dynamics Laboratory

The primary purpose of the laboratory ‘Thermal Engineering and Gas Dynamics’

is to show students the experimental method on various equipments like compressors and bomb calorimeter

and demonstrate their operational procedures. The objective of this lab is to provide good knowledge on

Thermal engineering and gas dynamics. The lab is well equipped and enables students to understand the

working and construction of compressors.

The lab also contains models of different condensers.

Major Equipment:

- 1. To study low pressure boiler and their accessories and mountings.

- 2. To study high pressure boiler and their accessories and mountings.

- 3. To prepare heat balance sheet for given boiler.

- 4. To study the working of impulse and reaction steam turbine

- 5. To find dryness fraction of steam by separating and throttling calorimeter.

- 6. To find the volumetric and Isothermal efficiency of double stage reciprocating air compressor

- 7. To find the condenser efficiencies.

- 8. To study and find expression for volumetric efficiency of a reciprocating air compressor.

- 9. To study cooling tower and find its efficiencies.

- 10. To find calorific value of a sample of fuel using bomb calorimeter.

List of Experiments:

- 1. Verify the condition of equilibrium of a body under the action of coplanar concurrent forces using universal force table.

- 2. Calculate moment of inertia of flywheel about its axis of rotation

- 3. Verify principle of moments of lever apparatus.

- 4. Verify Lami’s theorem using Jib Crane apparatus

- 5. Calculate coefficient of static friction of different material pairs using Combined Inclined Plane & Friction Apparatus.

- 6. Verify principle of moments of Bell Crank lever apparatus.

- 7. Compare the theoretical internal moment with the measured bending moment for a beam under various loads.

Advanced Materials Laboratory

Advanced Materials Laboratory

Advanced Materials Laboratory (AML) is a support facility for research and educational activities.

The lab provides services to the research communities and the students of the Rewa Engineering College,

Rewa (M.P). The vision of AML is to achieve excellence in materials research and education by combining local

resources and expertise to provide solutions to complex technical challenges in materials design, enhancement,

utilization, and identification

List of Instruments:

- 1. High-Temperature pin-on-disc Tribometer

- 2. Stir Casting Furnace

- 3. Metallography Belt Grinder

- 4. Double Disc Grinder

- 5. Precision Weighing Machine

- 6. Metal Cutting Machine

- 7. Ultrasonic Cleaner

RENEWABLE ENERGY LAB

Renewable Energy Laboratory

Renewable Energy Lab focuses on generating bio-gas from food waste produced by Rewa Engineering College,

Rewa using anaerobic digestion process.In our institute we have 3 hostels and all having their own individual mess,

daily a large amount of kitchen waste is obtained which can be utilized for better purpose.

This lab is established under the CRS project (ID: CRS -1-5728212545) and TEQIP-III.

The feeding is started with cow dung, which is available at Gausala near our college.

In second phase, we started for feeding to digester with the vegetable waste from vegetable shops (vegetable mandi of Rewa)

due to affect of COVID-19. Anaerobic digestion is a microbial process for production of biogas, which consists of primarily

methane (CH4) & carbon dioxide (CO2). Research will have process of carrying out survey,

characterization of kitchen waste from several kitchens & Canteens and knowing the potential for biogas production.

The waste generated from kitchen and vegetable waste is given as feedstock to produce 0.4 m3 of biogas per day.

The methane gas generated from Biogas is purified and this is used for power generation.

One biogas engine generator of 7 kVA was installed.

This power is used for backup power for renewable energy lab lighting and fan load.

This research lab is aimed to get the detailed information about biological reactions in biogas production

and Pressure Swing Adsorption (PSA) approach for biogas upgrading system based on biogas system which is installed at

Rewa engineering College, Rewa (Madhya Pradesh). The up-graded biogas is used in cooking, electric generation,

testing for gas storage bottling system and testing for Bio-methane Engine testing machines which are available in renewable energy lab.

List of Instruments:

- 1. Digester with Crusher Unit

- 2. Floater

- 3. Biogas Upgrading System (PSA Technique based)

- 4. Biogas Generator (Dual Fuel = Diesel and Biogas)

- 5. Biogas Flow Meter

- 6. Burner

- 7. pH meter

- 8. Bio Gas Analyzer

- 9. Biogas Compressor

- 10. Biogas Engine Testing Machine

- 11. Biogas Software

Other Facilities

Design Center

In design center, we have 30 workstations and one serverequipped with licensed software of mechanical engineering like CATIA, Abacus.

Smart Class Room

The Smart class room is a Remote Center jointly established by IIT Bombay & REC, Rewa. It is having 30 computers with digital Podium.

Seminar Hall- (G49)

The Seminar Hall of Mechanical Engineering Department is equipped with digital interactive board, Smart TV and Set Top Box for playing the MHRD SwayamPraha Channels. Live telecast of Programs like Prime Minister’s Mann Ki Baat and similar are shown here as per directions received by the MHRD, AICTE and the DTE. Besides this, NPTEL videos are played here as part of ICT classes.